Like I mentioned before, my water system is always under pressure. The insulated hot water tank with 45 liter capacity is mounted under the van is interconnected with the 200 liter tank in the garage. As the hot water is used, it is replaced by gravity from the tank above.

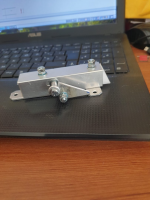

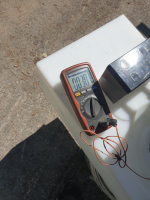

2 membrane pumps maintain the pressure in 2 small pressure reservoirs controlled by 2 electronic pressure transducers These allow me to set any desired pressure on the system. Initially I mounted the hot water pump next to the cold one but this is a high speed motor and the noise was terrible so I moved it to the outside mounted on a rubber sheet that dampens the vibration. The orange pump is the cold water one (had to use a hose and clamps because of the fitting that came with the pump but there is no pressure there so it shouldn't be an issue. On the hot water tank a 12v submerged heater is installed that only runs when the

battery is full or when the van is driving. This is usually deactivated because the

solar thermal heater works very well. There is a third re-circulation pump that takes the water to the panel to be heated. This is controlled by the system and waits for 2 hours after sun up to start testing for temperature. It measures the return water temperature and if higher than the tank it will carry on otherwise it stops. Usually by 15h00 the water is above 40ºC and at 45ºC the pump stops. In the following morning it's still above 30ºC

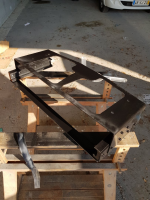

On the back of the bathroom wall I installed the water management system. 1- cold water pressure vessel, 2- hot water pressure vessel, 3- rear PLC control box, 4- automatic thermostatic shower mixer, 5- external shower solenoid valve, 6- internal shower solenoid valve, 7- electronic pressure transducers and 8- external shower quick disconnect. The shower water is push button controlled.