HTF

Forum Member

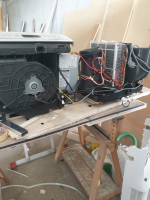

The rest of the electrical equipment is located under the back seat. I have 3 AGM 12v 95 aHr batteries running in parallel with space for a fourth. On top is a 1500 W/2000 W peak 230 v 50Hz pure sine wave inverter and on the right, the 40 A MPPT solar controller. There is an emergency manual cut off switch in case anything bad should happen but I think there are more than enough fuses to protect the wiring.

When I press the power up button, a certain sequence must happen to avoid damages. The PLC is powered up and the battery voltage measured and if ok, the sequence begins. The main power relay is energized first. It's important that the solar charger is connected to the batteries before the solar panel so, it's relay does this and then the solar, the pumps in sequence, the fridge and so on with the inverter connected last. All systems can be individually activated and deactivated by the PLC control panel. The PLC also monitors the van door lock/unlock condition and I'm able to do this remotely through my phone. When the van is started, the alternator voltage is checked and if necessary, the camper batteries are also connected to the alternator.

When I press the power up button, a certain sequence must happen to avoid damages. The PLC is powered up and the battery voltage measured and if ok, the sequence begins. The main power relay is energized first. It's important that the solar charger is connected to the batteries before the solar panel so, it's relay does this and then the solar, the pumps in sequence, the fridge and so on with the inverter connected last. All systems can be individually activated and deactivated by the PLC control panel. The PLC also monitors the van door lock/unlock condition and I'm able to do this remotely through my phone. When the van is started, the alternator voltage is checked and if necessary, the camper batteries are also connected to the alternator.